Tools of Note from the Woodworking in America 2013 Marketplace

Woodworking in America is absolutely nuts! It is frustrating and maddening because there is so much good stuff going on that no one person could ever catch it all. Its funny because even though I attended the show, I still find myself scouring over post show blog posts in the hopes of catching news from the stuff I missed. Watching Roy hew a log is one of them. It was a highlight of the show for so many, but I was down the hall watching Peter Galbert blow the minds of woodworkers. Peter Ross impressed a lot of people with his Blacksmith’s point of view on old tools. I was out in the hall deep in conversation with a Hand Tool School member I was dying to meet face to face discussing his issues with shooting boards. I’m sure we looked like a couple of fighter pilots discussing a dog fight as we gesticulated to each other mimicking the motion of the plane and body positioning. I heard some great things about Peter Follansbee’s Spoon carving class, but I was geeking out with Silas Kopf learning the technique differences between a marquetry horse and a Chevalet. I had to make the choice, I have no regrets, but this is one of the pervading themes of the entire show. How do I spend my time to get the best bang for my buck?

I bring this up because the WIA marketplace takes this entire experience and turns it up to 11. There is just no way to see everything other than skimming by. This is quickly becoming the Detroit Auto show of the woodworking world where the makers trot out their concept tools and shiny distractions to make the woodworker drool and his wallet cry. The beauty of the marketplace is that you can dive in deep and talk with the makers of fine tools, lay hands on them, and work some wood with them. You can ask the makers questions about why they designed a tool the way they did or why they chose the materials they did, what did the prototypes look like, and how/why did they change to what you see now. You can learn a lot about toolmaking and gain a much better understanding and respect for why they cost what they do. This year I spent A LOT of time in the marketplace, yet I feel like I still missed a lot of stuff (like the Lie Nielsen plow plane!). There is just no way to catch it all so you have to dig in where you can and hope someone else got some information on the rest of it. Here are some highlights for me:

Norm Reid and Jeff Fleischer started up Shenandoah Toolworks earlier this year because they wanted a better quality mallet for carving. Jeff is an accomplished carver and Norm is just one smart guy (Hand Tool School member) and both of them has a love of 18th Century furniture and its carved elements. In fact Norm is right now working on a reproduction of Thomas Jefferson’s lap desk on which he supposedly wrote the Declaration of Independence. I was excited to see these guys at WIA because I was fortunate to get one of their 1 lbs mallets in my hand months ago when Norm came to pick up some Mahogany from me at the lumber yard. I have been putting it through the paces and am really happy with it. The handle has two natural places to grip it whether you want power or finesse and the balance is just about perfect to use it easily. The angle on the mallet head is precisely determined so that you direct all the force of the blow right into the chisel our gouge you are using. Not just for carving, these weighty beauties can chop mortises with the best of them. I had their 1 lb version close at hand while I built my treadle lathe and it was there for every mortise and bridle joint. At WIA, I picked up the 1.5 lb version for a little more oomph on mortises. I really like the slightly extra kick this heavier version provides when I choke all the way up on the handle and use it for carving. The weight means the mallet does all the work and I don’t find myself having to even try to use it. The ergonomics and balance are such that it feels like it works all by itself. Shenandoah Toolworks also has some cool Chip Carving kits available too.

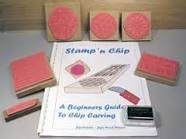

Norm Reid and Jeff Fleischer started up Shenandoah Toolworks earlier this year because they wanted a better quality mallet for carving. Jeff is an accomplished carver and Norm is just one smart guy (Hand Tool School member) and both of them has a love of 18th Century furniture and its carved elements. In fact Norm is right now working on a reproduction of Thomas Jefferson’s lap desk on which he supposedly wrote the Declaration of Independence. I was excited to see these guys at WIA because I was fortunate to get one of their 1 lbs mallets in my hand months ago when Norm came to pick up some Mahogany from me at the lumber yard. I have been putting it through the paces and am really happy with it. The handle has two natural places to grip it whether you want power or finesse and the balance is just about perfect to use it easily. The angle on the mallet head is precisely determined so that you direct all the force of the blow right into the chisel our gouge you are using. Not just for carving, these weighty beauties can chop mortises with the best of them. I had their 1 lb version close at hand while I built my treadle lathe and it was there for every mortise and bridle joint. At WIA, I picked up the 1.5 lb version for a little more oomph on mortises. I really like the slightly extra kick this heavier version provides when I choke all the way up on the handle and use it for carving. The weight means the mallet does all the work and I don’t find myself having to even try to use it. The ergonomics and balance are such that it feels like it works all by itself. Shenandoah Toolworks also has some cool Chip Carving kits available too.  They aren’t up on the web site yet, but Jeff, an accomplished chip carver, has created some nice practice patterns in rubber stamp form that allows you to quickly and accurately layout patterns on your board in an instant so you can get right to work with the knife. I have never seen this before and it is a really intriguing option for the person wanting to dive into chip carving or perhaps the craftsman that does a lot of standard chip carved borders where he will want to layout the same thing time and again.

They aren’t up on the web site yet, but Jeff, an accomplished chip carver, has created some nice practice patterns in rubber stamp form that allows you to quickly and accurately layout patterns on your board in an instant so you can get right to work with the knife. I have never seen this before and it is a really intriguing option for the person wanting to dive into chip carving or perhaps the craftsman that does a lot of standard chip carved borders where he will want to layout the same thing time and again.

Lee Valley/Veritas is always full of great ideas and they take an innovative approach to hand tools. They are releasing a Butt Mortise plane which is a highly specialized tool for making hinge mortises with perfectly square edges to a precisely controlled depth. Lie Nielsen has had one of these on the market for some time and Deneb Pulchalski did a good video of it in use. Personally I have never found a use for this tool as the same task can be done quickly with a chisel and router plane. Veritas has taken this chisel and router plane idea and made their Butt Mortise plane to function much like their router plane, in fact it uses the same blade set up with a faceted post. So while I don’t put much stock in a specific hinge mortising plane, I can see some uses in using this plane to trim tenon cheeks or half laps where a wider wheel base is needed. Even throwing the plane out of the equation, I could really see some benefit to buying only the blade (I’m told this will be an option) which is 3/4″ wide and inserting it into my existing Veritas router plane so I could more quickly level the floor of wider dados and tenon cheeks. Maybe there is finally an answer to the “kickback that wouldn’t die” from WoodTalk and we finally have a solution to trim tenon cheeks that everyone can agree upon.

Lee Valley/Veritas is always full of great ideas and they take an innovative approach to hand tools. They are releasing a Butt Mortise plane which is a highly specialized tool for making hinge mortises with perfectly square edges to a precisely controlled depth. Lie Nielsen has had one of these on the market for some time and Deneb Pulchalski did a good video of it in use. Personally I have never found a use for this tool as the same task can be done quickly with a chisel and router plane. Veritas has taken this chisel and router plane idea and made their Butt Mortise plane to function much like their router plane, in fact it uses the same blade set up with a faceted post. So while I don’t put much stock in a specific hinge mortising plane, I can see some uses in using this plane to trim tenon cheeks or half laps where a wider wheel base is needed. Even throwing the plane out of the equation, I could really see some benefit to buying only the blade (I’m told this will be an option) which is 3/4″ wide and inserting it into my existing Veritas router plane so I could more quickly level the floor of wider dados and tenon cheeks. Maybe there is finally an answer to the “kickback that wouldn’t die” from WoodTalk and we finally have a solution to trim tenon cheeks that everyone can agree upon.

I have said so much about Scott Meek’s wooden hand planes before now and I have 3 of them that get daily use. What else is there to say other than what are you waiting for? This year I spent a lot of time at Scott’s booth to help him out when he needed a break. I was supposed to cut some mouldings using my Time Warp Toolworks planes but the opportunity never came up. Frankly this was because too many people were ga-ga for Scott’s planes. He has changed the design a bit on his larger planes to include a very organic looking hump (I prefer to call it a nipple) right behind the wedge. This cradles your hand and make it very comfortable to use. While I was using them I couldn’t help but notice how naturally my hand fell into position without thinking about it and how easy it was to use the plane. Scott’s design not only directs the force exactly where you need it, he has put a lot of thought into body mechanics and how one holds these planes. I seems as though Scott has unlocked the perfect hang angle for a plane. Maybe it is because he has spent so much time in close proximity to great saw makers. This year Scott had Bad Axe Toolworks on the left and Blackburn Toolworks (my source for resaw frame saw blades) on the right. I came away with one of Scott’s small jointers and have already put it to work in my own shop jointing the backs of some crown mouldings I made for a commission. You can really plane for hours without fatigue using this plane because it fits so naturally. The one I have is left handed even!

I have said so much about Scott Meek’s wooden hand planes before now and I have 3 of them that get daily use. What else is there to say other than what are you waiting for? This year I spent a lot of time at Scott’s booth to help him out when he needed a break. I was supposed to cut some mouldings using my Time Warp Toolworks planes but the opportunity never came up. Frankly this was because too many people were ga-ga for Scott’s planes. He has changed the design a bit on his larger planes to include a very organic looking hump (I prefer to call it a nipple) right behind the wedge. This cradles your hand and make it very comfortable to use. While I was using them I couldn’t help but notice how naturally my hand fell into position without thinking about it and how easy it was to use the plane. Scott’s design not only directs the force exactly where you need it, he has put a lot of thought into body mechanics and how one holds these planes. I seems as though Scott has unlocked the perfect hang angle for a plane. Maybe it is because he has spent so much time in close proximity to great saw makers. This year Scott had Bad Axe Toolworks on the left and Blackburn Toolworks (my source for resaw frame saw blades) on the right. I came away with one of Scott’s small jointers and have already put it to work in my own shop jointing the backs of some crown mouldings I made for a commission. You can really plane for hours without fatigue using this plane because it fits so naturally. The one I have is left handed even!

Sterling Toolworks technically didn’t exhibit at the show but their story is something I would like to highlight. Chris Kuehn is a friend and neighbor of mine and a HUGE fan of Chris Schwarz. When he recently traveled to the Woodwright’s School to take the Anarchist Toolchest class Chris saw first hand a dovetail layout tool Chris Schwarz had and decided to put his engineering and machinist skills to work and make one. Ever the entrepreneur, Chris then founded Sterling Toolworks and proceeded to crank out the first run of his Saddle-Tail layout tool in lovely brass and steel. One side side is a 1:4 Dovetail and the other side of the T shape is a square. The brass handle is hefty and has a nice recess ground in where your fingers perfectly fall while laying out your dovetails. The balance is perfect so you actually don’t even have to grip it while working. I have one of these (payment for helping to set up the web site and taking the product photos) and I have enjoyed using it. Chris attended the show and sold out of his first production run just walking around the marketplace floor. Moreover, he sold them to some woodworking celebrities so I expect you will hear more about the Saddle-Tail from others. It is a cool story of the birth of a boutique toolmaker and stuff like this why we are in a hand tool renaissance right now. Good luck to Sterling Toolworks!

Sterling Toolworks technically didn’t exhibit at the show but their story is something I would like to highlight. Chris Kuehn is a friend and neighbor of mine and a HUGE fan of Chris Schwarz. When he recently traveled to the Woodwright’s School to take the Anarchist Toolchest class Chris saw first hand a dovetail layout tool Chris Schwarz had and decided to put his engineering and machinist skills to work and make one. Ever the entrepreneur, Chris then founded Sterling Toolworks and proceeded to crank out the first run of his Saddle-Tail layout tool in lovely brass and steel. One side side is a 1:4 Dovetail and the other side of the T shape is a square. The brass handle is hefty and has a nice recess ground in where your fingers perfectly fall while laying out your dovetails. The balance is perfect so you actually don’t even have to grip it while working. I have one of these (payment for helping to set up the web site and taking the product photos) and I have enjoyed using it. Chris attended the show and sold out of his first production run just walking around the marketplace floor. Moreover, he sold them to some woodworking celebrities so I expect you will hear more about the Saddle-Tail from others. It is a cool story of the birth of a boutique toolmaker and stuff like this why we are in a hand tool renaissance right now. Good luck to Sterling Toolworks!

Vogt Toolworks is always worth stopping by and as an owner of a Super Chute I am always keenly aware of the little enhancements Tico makes that essentially make my version of the Chute obselete. (sigh) This year Tico was showcasing the bevy of dedicated shooting planes based off the Stanley 51. If you are skeptical of this plane like I have been then this was a perfect opportunity to see what they are all about. I have to say as effective as my low angle Jack plane has been for years, these new shooting planes are a force to be reckoned with and getting to use them has be rethinking if this plane has a place in my shop. What was really cool was Tico went off the deep end and partnered up with Ron Brese to create the perfect shooting experience. Ron’s 10 lb infill shooter paired with a steel plate that runs in a track on the shooting board created a shooting experience that was unlike anything I have ever seen. Tico said it best when he commented that his biggest thrill came from the look on woodworkers’ faces when they tried it out for the first time. It is truly amazing to see what happens when no holds are barred.

Vogt Toolworks is always worth stopping by and as an owner of a Super Chute I am always keenly aware of the little enhancements Tico makes that essentially make my version of the Chute obselete. (sigh) This year Tico was showcasing the bevy of dedicated shooting planes based off the Stanley 51. If you are skeptical of this plane like I have been then this was a perfect opportunity to see what they are all about. I have to say as effective as my low angle Jack plane has been for years, these new shooting planes are a force to be reckoned with and getting to use them has be rethinking if this plane has a place in my shop. What was really cool was Tico went off the deep end and partnered up with Ron Brese to create the perfect shooting experience. Ron’s 10 lb infill shooter paired with a steel plate that runs in a track on the shooting board created a shooting experience that was unlike anything I have ever seen. Tico said it best when he commented that his biggest thrill came from the look on woodworkers’ faces when they tried it out for the first time. It is truly amazing to see what happens when no holds are barred.

I have already raved about Peter Galbert‘s influence on my WIA experience but if you can believe it, his booth in the marketplace made it even better. Peter and a few of his friends have made it their mission to start creating dedicated tools for chair makers. Peter said it in his seminars that chair makers have too long just made do with tools from other trades. This booth was home to the now famous DrawSharp and the time tested Galbert Caliper. I have owned and used the caliper for probably 5 years now and I placed my order for the DrawSharp at the show (they were sold out faster than San Diego ComicCon tickets). I also own one of Peter’s Travishers and used it to hollow the seat on my last Windsor chair. That was a revelation to use and those were on display and in use in the booth. Tim Manney was there showing off his reamers which takes an age old tool and integrates some stupid simple enhancements to make it simply a joy to use. Things like a straight shaft so you don’t have to offset your bevel gauge from the resultant angle to half the taper of the reamer. This is a perfect example of how chair makers have “made do” and how Peter and his friends are changing that. What really got me excited was Tim’s version of a new adze. At first glance this looks paleolithic but watching it work was very impressive. Really any tool in the hands of a talented craftsman is impressive but the real epiphany was when I picked it up and made some chips myself. Tim and Peter has worked together to precisely shape the handle and angle of the blade to all but eliminate the learning curve on using this tool. It works so naturally with your body’s natural movement that within minutes I was “following the chip” across the board and into the hollow of a seat. Needless to say I added my name to the waiting list on this tool. I expect some really innovative things to come out of this tool makers “cooperative” in the next few years.

I have already raved about Peter Galbert‘s influence on my WIA experience but if you can believe it, his booth in the marketplace made it even better. Peter and a few of his friends have made it their mission to start creating dedicated tools for chair makers. Peter said it in his seminars that chair makers have too long just made do with tools from other trades. This booth was home to the now famous DrawSharp and the time tested Galbert Caliper. I have owned and used the caliper for probably 5 years now and I placed my order for the DrawSharp at the show (they were sold out faster than San Diego ComicCon tickets). I also own one of Peter’s Travishers and used it to hollow the seat on my last Windsor chair. That was a revelation to use and those were on display and in use in the booth. Tim Manney was there showing off his reamers which takes an age old tool and integrates some stupid simple enhancements to make it simply a joy to use. Things like a straight shaft so you don’t have to offset your bevel gauge from the resultant angle to half the taper of the reamer. This is a perfect example of how chair makers have “made do” and how Peter and his friends are changing that. What really got me excited was Tim’s version of a new adze. At first glance this looks paleolithic but watching it work was very impressive. Really any tool in the hands of a talented craftsman is impressive but the real epiphany was when I picked it up and made some chips myself. Tim and Peter has worked together to precisely shape the handle and angle of the blade to all but eliminate the learning curve on using this tool. It works so naturally with your body’s natural movement that within minutes I was “following the chip” across the board and into the hollow of a seat. Needless to say I added my name to the waiting list on this tool. I expect some really innovative things to come out of this tool makers “cooperative” in the next few years.

There is so much more that can be said in this already long post and if I left out anybody I do apologize. I always leave WIA so jazzed up about our craft but this year to see so many new faces in the marketplace was really exciting. Will this tool renaissance end? Though my wallet disagrees, I sincerely hope that it keeps going for many more years.

Your Turn

Did you visit the WIA marketplace? What tools/companies stood out to you and why? Please leave a comment below and share your experience.