Treadle Lathe Tool Rest Detail

In my last article about my treadle lathe improvements I neglected to include photos of my new tool rest. Mainly because like most of my tool building experiments, I tend to start using them before I finish them. So over the last 2-3 weeks since I made my improved rest, it has retained its bulky, square appearance. Last night I decided to put some vintage Woodwright Shop on the TV, grab a rasp and finally shape the banjo of my treadle lathe. While I briefly discussed it in my last post I will review it here again because I find that the tool rest is usually forgotten about in lathe construction. In my research before building mine I often found sentences like, “…now build a tool rest and start turning.” or, “…add a tool rest and your lathe is done.” and these tell us nothing of how the rest was built. So to the future generations of crazy galoots who want to build a foot powered lathe, this is for you.

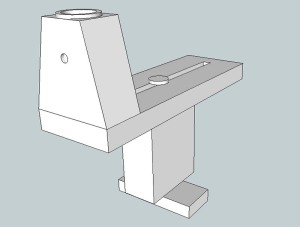

At the base of the lathe is my banjo mechanism that allows me to slide the rest up and down the bed, in and out, and in an arc. It starts with a 1″ thick piece of hardwood that is 3″ wide and 12″ long. I cut a long slot down the middle that is dimensioned to exactly capture the square collar of a 1/2″ carriage bolt. That bolt is my pivot point for the banjo.

At the base of the lathe is my banjo mechanism that allows me to slide the rest up and down the bed, in and out, and in an arc. It starts with a 1″ thick piece of hardwood that is 3″ wide and 12″ long. I cut a long slot down the middle that is dimensioned to exactly capture the square collar of a 1/2″ carriage bolt. That bolt is my pivot point for the banjo.

So as to take up any slop as the rest moves, I added a guide block. This block is precisely sized so that it slips between my bed rails. It is thin enough to move wit ease between the rails but only just so that it removes any excess wiggle. A 1/2″ hole is drilled through the middle and the block is a bit narrower than the width of the rails. I made mine about 4″ long though that is a pretty arbitrary number.

Below the guide block is the clamp block. This is a 3/4x2x5 piece of hardwood with another 1/2 hole drilled through the center. When I swivel it so that the long axis is perpendicular to the lathe bed it secures the entire rest in place. I added a washer then a threaded handle nut below to provide the clamping pressure. I made it to be a separate piece so that I can swivel it parallel to the bed and the tool rest can be lifted out between the rails without having to take it apart.

This mechanism is essential and I have used it on both my treadle and my pole lathes.

Above the banjo is the rest itself and while a rigid block of hardwood is used on my pole lathe, I wanted even more flexibility on the flywheel treadle lathe to rotate the rest itself for faceplate work. Taking a cue from a modern lathe rest, I laminated together a block that is 4″ thick, 2″ wide, and 3″ long. I bored a 1 3/8″ hole through the middle and glued in a 1″ inner diameter steel pipe with 3/16″ thick walls. I crossed drilled the post and pipe then tapped it to receive a locking handle I picked up for a few bucks from McMaster Carr (I love that place). This would be my locking mechanism to secure the rest where I want it and the steel pipe provides a piston fit for any commercially available tool rest with a 1″ post. I glued and screwed this block to my banjo block then rounded the edges and shaped the whole thing with my rasps and files until I was happy with the shape.

Above the banjo is the rest itself and while a rigid block of hardwood is used on my pole lathe, I wanted even more flexibility on the flywheel treadle lathe to rotate the rest itself for faceplate work. Taking a cue from a modern lathe rest, I laminated together a block that is 4″ thick, 2″ wide, and 3″ long. I bored a 1 3/8″ hole through the middle and glued in a 1″ inner diameter steel pipe with 3/16″ thick walls. I crossed drilled the post and pipe then tapped it to receive a locking handle I picked up for a few bucks from McMaster Carr (I love that place). This would be my locking mechanism to secure the rest where I want it and the steel pipe provides a piston fit for any commercially available tool rest with a 1″ post. I glued and screwed this block to my banjo block then rounded the edges and shaped the whole thing with my rasps and files until I was happy with the shape.

I think it looks cool and more importantly it is rock solid with no amount of flex anywhere in the system. Plus I can swap other rests in and out very easily just like a modern lathe. This is definitely my final design for the tool rest. I can’t imagine how I could improve it any further. In fact I’m probably going to make another one to act as a second support for longer 24-36″ rests for turning chair and table legs. After all the total cost was some scrap wood and about $8 in hardware from McMaster Carr.

Finally here is a short clip of the rest in action. You’ll also notice the smooth action of the lathe since I replaced the spindle with an actual hardened drive shaft that is straight to a much higher tolerance than my previous cold rolled steel.

Dec 26, 2013 | New treadle Lathe tool rest and new drive shaft by RenaissanceWW on Keek.com

Dec 26, 2013 | Burning off the Christmas cookies on the treadle lathe by RenaissanceWW on Keek.com