Tool Undercoating

I think it is safe to say that for today’s woodworker tool buying is as much a part of the experience as actually working wood. For better or for worse is a matter of opinion and I’m going to stay positive and say that without tool buying much of the economy of woodworking would fall apart. No woodworker can deny the siren song of buying a new tool and today we are very fortunate to have a lot of tools to choose from. Whether you need it right now or not, a new tool represents possibility. Maybe you don’t think you could execute a task without the tool or you think it will make a task faster or better with this tool. It is the potential this new tool can unlock that is intoxicating.

I think it is safe to say that for today’s woodworker tool buying is as much a part of the experience as actually working wood. For better or for worse is a matter of opinion and I’m going to stay positive and say that without tool buying much of the economy of woodworking would fall apart. No woodworker can deny the siren song of buying a new tool and today we are very fortunate to have a lot of tools to choose from. Whether you need it right now or not, a new tool represents possibility. Maybe you don’t think you could execute a task without the tool or you think it will make a task faster or better with this tool. It is the potential this new tool can unlock that is intoxicating.

I write this preamble as a disclaimer that I see nothing wrong with buying new tools to scratch that itch. Supporting the makers is important to keep the market alive. However, buying a new tool because you think some additional feature will change the way you work could be a frustrating move that may even set you back in your growth as a woodworker. Today as in the past, tool manufacturers abound with slick options and features that will make their tools work better. These additional features cause a lot of confusion and create sales where there are none now. In our option heavy society, we want to super size our tools and get the works. While you may consider sour cream, chives, and bacon essential to your baked potato experience I am hesitant to say similar options in the tool world are anything more than infamous undercoating.

Gimmick or Useful?

What do these additional features really add to the performance and ease of use for your tools? Does it really change the game or is is just a gimmick to bring people back to the cash register? Let’s look at some hand tool examples on the market today.

What do these additional features really add to the performance and ease of use for your tools? Does it really change the game or is is just a gimmick to bring people back to the cash register? Let’s look at some hand tool examples on the market today.

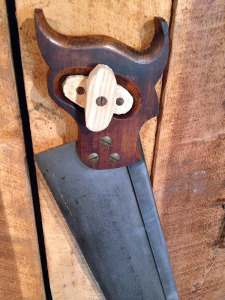

Canted Saw Plates

This basically means the width of saw plate beneath the toe of the saw is narrower than at the heel. This feature will prevent you from sawing past your line on the far side of your workpiece by accident since the heel side will reach the depth first. A second advantage is that the angled presentation of the teeth makes for faster, easier sawing. I call gimmick on this. The baseline argument assumes that the sawyer is keeping the back of the saw parallel to the work. Spend any time with a back saw and you will find that angling the saw slightly and working your line across the board, sometimes from the far side toward you, sometimes the opposite, is the best way to accurately saw to a knife line or pencil line. In fact the really nice saws are hung (simply put, the angle between the handle and the tooth line) so that this angled presentation is the natural way the saw is used. Moreover the tooth geometry is matched so that optimal cutting happens at this natural hang angle. It seems to me that the canted blade is just messing with something that already happens when attention is paid to the hang angle in the first place. This feature is not new certainly as it is found in many vintage saws. However just because it was used back then doesn’t mean it is right. In fact I think hand tools were more prone to gimmicks back in the day when more people used them and more competition existed. I have worked with both canted and uncanted blades new and vintage and I can honestly state that the difference is negligible but leaning toward a proper hung saw and un-canted blade.

Thin Plate Saws

The thin plate creates a narrower kerf and allows for more precise cuts and easier work. It makes sense that the less wood that is removed the easier the work will be. Also a gimmick in my opinion. The specs will vary from maker to maker but on average the difference between a thin kerf and “regular” kerf saw is .004″. Somehow I don’t think the perceived effort is any different and if so, I think I can handle that extra work. Maybe it will help me burn off that stick of gum I just chewed. As far as accuracy, are any of us cutting joints that are so small and need to be so accurate that this reduced kerf will actually make a difference? In reality I think more problems arise with a thinner plate that could be more fragile. A beginner sawyer is going to be more likely to bend and kink the plate. I have no data on this but I have to believe that the thinner steel will heat up faster and expand more readily in use. I wonder what the actual kerf is after the plate heats up? With an average difference of 4 thousandths it wouldn’t take much before that margin is gone. Then again how much continuous sawing does one do with a dovetail saw. And the thin plate saws really are all dovetail saws. If a larger back saw was made to be thin kerf it had better have a bamboo wrapped handle and be meant to be pulled or I would run the other way.

Folded Backs

Instead of a solid piece of brass or steel or whatever with a groove cut in it and glued to the saw plate, the folded saw back is folder over and holds the plate in tension. On this feature I say useful. (you thought this was going to be all negative didn’t you?) With a folded back holding the plate in tension, you can easily adjust and re-tension the blade if you kink it. Moreover, the folded back provides a safety mechanism of sorts that allow the blade to move instead of causing harm to the tooth line with a rigid plate. Think about how your skis are designed to pop off your feet when you yard sale all over the ski slope and what shape your knees would be in if the skis didn’t come off. Folded backs are more expensive because it takes more work to execute but I think you will find they make for a better saw that will be more durable and stand up to the mistakes that beginner and advanced sawyers make.

Instead of a solid piece of brass or steel or whatever with a groove cut in it and glued to the saw plate, the folded saw back is folder over and holds the plate in tension. On this feature I say useful. (you thought this was going to be all negative didn’t you?) With a folded back holding the plate in tension, you can easily adjust and re-tension the blade if you kink it. Moreover, the folded back provides a safety mechanism of sorts that allow the blade to move instead of causing harm to the tooth line with a rigid plate. Think about how your skis are designed to pop off your feet when you yard sale all over the ski slope and what shape your knees would be in if the skis didn’t come off. Folded backs are more expensive because it takes more work to execute but I think you will find they make for a better saw that will be more durable and stand up to the mistakes that beginner and advanced sawyers make.

Adjustable Mouth Planes

I’m a bit “meh” on this option. If you only have 1 or 2 planes then I can see being able to adjust the mouth opening to accommodate a thicker shaving/chip. As an everyday plane user with a nice selection of planes to handle each stage of milling and joinery I can say that I rarely, if ever, change this setting. My rough and medium planes are set for that purpose and my smoothing and finished surface tools only do that job. Also, I work primarily with happy hand tool domestic species that don’t require a super tuned plane to control tear out. I find that a medium mouth opening is more than sufficient for jointing and smoothing and only my Fore plane and Scrub plane requires a wider mouth. So I’m on the fence as I can see it being useful, but I certainly wouldn’t use this feature as basis for buying or not buying a plane. If you want this feature solely to control tear out consider whether the woods you work really demand it.

Progressive Pitch/Rake/Fleam

This is the practice of gradually changing the tooth geometry on a saw. Sometimes it is smaller teeth that get larger along the lengths and more simply it is a more relaxed rake with greater fleam that glides over the wood and makes the saw easier to start. I say gimmick! This may be a surprise to some of you as I myself used to think this was a great thing that turned a saw from good to great. Then it came time to resharpen it and I found it confusing and annoying to have to adjust the geometry along the plate. This is one area of sharpening where I still use a guide and having to stop and change settings is really inconvenient. Maybe one day I’ll ditch the guide but I still can’t see this changing my mind. I you pay more attention to your body mechanics and sawing technique I think you can solve any problem that you would try to solve my gerrymandering the teeth of the saw. I did a Hand Tool School demonstration about a year ago on starting a saw and illustrated that by taking the weight off the toe you can start just about any saw easily. With no starting back stroke. I successfully started a 5 ppi 28″ rip saw with no rake or fleam in Ipe (a wood that makes granite cry) with a single, light forward stroke. That doesn’t make me a savant, just aware of the weight at the toe of the saw. Messing around with this progressive stuff just complicated things and is nothing but a gimmick.

Higher Angle Frogs

This is another option that isn’t new as you will find many vintage wooden planes with higher bed angles and you will find some mention to higher angle frogs in the last century with metal planes. It seems like this additional frog and even the additional, higher bevel angle blade idea has really become popular in recent years. I’m not going to call this a gimmick because it does work to control tear out on really gnarly woods, but I will call it somewhat unnecessary. Unless you work with HEAVILY figured woods born deep in the rainforests that are harder than granite and have grain patterns more interlocked than a DNA strand I think your tear out problems can be correct in other ways. A tight mouth, sharp blade, and good chip breaker position will solve this problem without having to swap blades or change the frog and without increasing the level of effort to push the plane.

I think I’ll stop there. There are some more things that I could probably come up with and I realize that I’m only talking about hand tools. I think the power tool makers are more guilty of this and have a lot more gimmicks built in to their tools. Can you say laser? But I would be speaking on that subject from a several year old perspective since my power tools and their gimmicks are currently taking up space in other woodworker’s shops now.

So What’s Wrong with Gimmicks?

Hey I like lasers as much as the next guy but what happens when the battery dies and I don’t know how to line up a cut or level a picture without that laser. What skills am I skipping and not learning? When I get tear out on a board do I just go buy a different plane or do I try to solve the problem with what I have using my knowledge of wood and how a blade actually cuts? Your answers will probably be different than mind and I do think in some instances getting that new tool may be the path of least resistance. You will also find that a gimmick free tool may not exist anymore. When was the last time you could buy a car without power windows and locks?

Gimmicks and options can be a lot of fun but the minute you start thinking that your perfectly good tool won’t work now because it isn’t canted with a laser line and kung-fu grip you need to stop and think about what these features really will add to your woodworking experience.

So what do you think?

Maybe I’m getting old and set in my ways and feel the need to bad mouth options that “kids today” have on their tools. I would love to hear from you whether you think the above are gimmicks or what other options you think might be useful or just gimmicks. Ready? Go!