Yes Wood Moves, but it Doesn’t MOVE!

I get a lot of questions about wood every day. Whether I’m wearing a Renaissance Woodworker/Hand Tool School hat or a J. Gibson McIlvain hat I’m getting these questions. This started almost as soon as I starting working at the lumber yard and while I thought I knew a fair amount already I had to learn a lot more really fast. So I developed a “system” (my boss calls it the “wood info matrix”) to help me quickly identify how a species would work as compared with a species I already have experience. Then I tested it by putting blade to lignin on those unknown species. I discovered quickly that I was able to closely identify how a wood would behave by examining and comparing just a few attributes. That is at the heart of my upcoming webinar with Popular Woodworking and I hope many of you will join me Wednesday night and learn something useful.

I get a lot of questions about wood every day. Whether I’m wearing a Renaissance Woodworker/Hand Tool School hat or a J. Gibson McIlvain hat I’m getting these questions. This started almost as soon as I starting working at the lumber yard and while I thought I knew a fair amount already I had to learn a lot more really fast. So I developed a “system” (my boss calls it the “wood info matrix”) to help me quickly identify how a species would work as compared with a species I already have experience. Then I tested it by putting blade to lignin on those unknown species. I discovered quickly that I was able to closely identify how a wood would behave by examining and comparing just a few attributes. That is at the heart of my upcoming webinar with Popular Woodworking and I hope many of you will join me Wednesday night and learn something useful.

However it is only an hour long and this is a topic that could take years to cover completely. So here is something that I WON’T cover in the webinar that I think needs to be understood better.

Wood Moves, Get Over It

The above is the title of an article I wrote on the McIlvain lumber website. To this day it is one of the most visited pages in our blog. (If I had known that in advance, I probably would have written it better)

The gist is that there is nothing to do about wood movement but accept it. You can’t stop so work with it. I think we as woodworkers understand this better than most, but I think many of us have an inflated sense of how much wood moves. This has us constantly worried about cross grain situations like they are poised to go off like a bomb. The reality is wood doesn’t move that much when you start thinking on furniture scales.

Its’ a percentage thing

Its’ a percentage thing

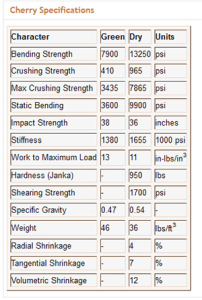

Check out any wood species specification chart and you will find several bullet points relating to movement. The ones to look at are: tangential and radial shrinkage. They are measured in percentages. I know this will sound pretty obvious but lets remember that the percentage of a small number will be smaller than the same percentage of a larger number.

Duh right? So why do we get so caught up in worrying about wood movement?

Let’s talk real for minute. On furniture scales the resultant total movement is really quite small. For instance using the Cherry specs shown and assuming a typical drawer side of 4″ wide this board will move just over 1/4″. The tangential shrinkage (flat sawn board for the side) is 7% and:

.07 x 4 = .28″

A quarter of an inch is a pretty big deal and visions of drawers stuck in a cabinet or forcing drawer blades in a rictus like the Joker come to mind. Remember however this is the total shrinkage and this movement is caused by changes in the surrounding environment. This is where equilibrium moisture content (EMC) must be considered. As the temperature and relative humidity change, wood will move until is comes into equilibrium. Plainly stated this is the point where no moisture is coming or going in the board and its movement is stable. If your board is at this EMC when the drawer is built and no change occurs in the environment around it, that drawer side won’t move at all. This rarely if ever happens as we move things out of our shops into the house or sell them to customers in different regions where the average EMC is different. The Forest Products Laboratory has a chart of average EMC in many cities if anyone is interested. This PDF also has some good wood drying information in general too but the EMC chart is on page 15. On page 17 you will find a chart of EMC for various temperatures and relative humidity.

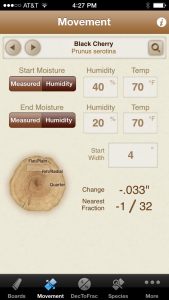

The Woodshop Widget is a great app for this kind of stuff

What is most relevant here is that little to no reaction can be expected from the wood when the EMC change is under 2%. You get that for free and can begin calculation movement above 2% change in EMC. Now these average numbers refer to outside conditions and unless you are building exterior furniture they are irrelevant. Interior conditions for the typical climate controlled home are 70 degrees and 40% relative humidity or an EMC of around 7%. This will change seasonally and in the winter when the heat is running more often you can expect the EMC to drop to around 4% (70 degrees at 20% humidity). So taking that 2% freebie away and now going back to our theoretical drawer side we will find that there is only a 1% change in environment and little to no movement will occur. If you look at the screen shot from my phone using The Woodshop Widget you see that we can expect only about 1/32″ of movement in the tangential direction. Personally I think this high and is probably a rounded up number when you consider the small EMC change.

Additionally this moisture exchange is not an instant thing. Kiln dried wood absorbs moisture slower than air dried due to baked and hardened cell walls. Finish on the wood slows the moisture exchange even further. So not only do we need to pay attention to the EMC but a prolonged change in EMC. This slower exchange is what we count on to keep our boards flat as they move. Also when a board is joined in place the restraint provided is usually enough to maintain flatness. Or if your project is taking a long time and the boards are unrestrained, weight it down to encourage that restraint. This is how we air dry our lumber at McIlvain. Notice how the weight of the wood on top keeps the wood flat and the top pack is wrapped in steel bands to keep it in check

Additionally this moisture exchange is not an instant thing. Kiln dried wood absorbs moisture slower than air dried due to baked and hardened cell walls. Finish on the wood slows the moisture exchange even further. So not only do we need to pay attention to the EMC but a prolonged change in EMC. This slower exchange is what we count on to keep our boards flat as they move. Also when a board is joined in place the restraint provided is usually enough to maintain flatness. Or if your project is taking a long time and the boards are unrestrained, weight it down to encourage that restraint. This is how we air dry our lumber at McIlvain. Notice how the weight of the wood on top keeps the wood flat and the top pack is wrapped in steel bands to keep it in check

This is very little movement at the worst case and your home may see even less change throughout the year. So taking this even further and looking at joinery situation we see even smaller dimensions. Think about that 1/2″ thick by 2″ wide tenon and you can figure the movement there is pretty much negligible. I get questions like this all the time where someone worried that his such and such joint will cause his project to fall apart. The reality is there is very little to worry about. We also have to remember that wood is anisotropic which means it does not move equally in all directions. (and 35 points in Scrabble) So determining the orientation of the wood and the related movement there may turn up even less movement.

Don’t get me wrong, I don’t want anybody to ignore the fact that wood moves. The best thing we can do is understand it and confidently make decisions in our construction. Right now I see many woodworkers lost in this mystical force that moves wood at random and every cut, every joint is a roll of the dice. At best this movement is little to worry about, at worst, do some match (gasp) and build to accommodate the movement.

Additional Resources

I’m simplifying a lot here on purpose because we woodworkers tend to over complicate everything. If you want to learn more please do check out the above mentioned PDF and here is a great article from Penn State that covers EMC nicely. (thanks for the link Bob)