A Peg Making Hook and Shooting Board Addition

Snick, thump, snick, thump, snick, thump, mother friggin $#@o0%!!!, snick, thump…

Do you have those little nagging things in the workshop that you keep meaning to fix or improve but just never get around to it? Usually I’m in the heat of a project and I just don’t want to stop and fix something or make that extra special storage place to house a tool. Sometimes, like right now, one of my bench appliances is missing something that didn’t seem important when I built it. Yet I trudge on not wanting to stop what I’m doing to devise a solution. Kinda like when I use my panel shooting board and the long panel doesn’t have infeed support so it won’t stay flat on the shooter and thumps down on the bench after every plane stroke. Yeah I’ve been dealing with that for 5 years now!

Eventually you need to stop what you are doing and just build some solutions. So I took a time out from my blanket chest project to fix some nagging things around the shop. The thing is when I’m building bench hooks and stuff I go light and fast and build around the dimensions of scrap I have laying about. If I have to stop working I’d rather do it quick and use up some scrap.

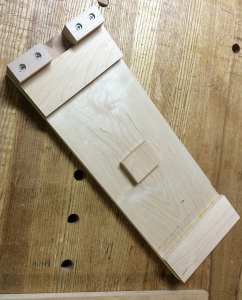

First I needed to create a support for the panel shooter. I needed a hook that was more than 1.5″ thick to bring it level with the shooting board. I didn’t have any scrap that would match that thickness and I wasn’t going to pull a fresh board from the shed and start planing it down to that thickness. So I improvised and just glued some blocks onto the bottom of a 1″ thick board then screwed a cleat to it. Ta da, 5 years of making do with this shooting board and I fixed it in 5 minutes. Why the heck didn’t I do this years ago.

First I needed to create a support for the panel shooter. I needed a hook that was more than 1.5″ thick to bring it level with the shooting board. I didn’t have any scrap that would match that thickness and I wasn’t going to pull a fresh board from the shed and start planing it down to that thickness. So I improvised and just glued some blocks onto the bottom of a 1″ thick board then screwed a cleat to it. Ta da, 5 years of making do with this shooting board and I fixed it in 5 minutes. Why the heck didn’t I do this years ago.

Next I decided that while I was in problem solving mode that I would finally make a bench hook for making pegs. I have a dowel plate that I’ve used for years but I have been hesitant to fix it to anything as I prefer it loose so I can throw it in a toolbox or apron pocket when I need it outside the shop. I bought the Veritas Dowel Former kit a few months ago thinking it would be a good permanent solution for in the shop but didn’t get any farther than that.

So with a few pieces of scrap, some screws, and a V gouge I had created a Peg making hook. Everything from sawing the wood to peg length, riving out blanks, planing them close to size, then of course driving through the plate is now contained in this handy dandy hook. I can pop it onto the bench, crank out a bunch of pegs then move it out of the way.

So with a few pieces of scrap, some screws, and a V gouge I had created a Peg making hook. Everything from sawing the wood to peg length, riving out blanks, planing them close to size, then of course driving through the plate is now contained in this handy dandy hook. I can pop it onto the bench, crank out a bunch of pegs then move it out of the way.

I’ve only been thinking about doing this one for a few years so my turnaround was pretty good this time. Now in hindsight, I’m really kicking myself for not making both of these hooks when I first realized I needed them. It is funny how much time I lose or stuff I put up with because I “don’t have time” to stop and devise a solution.

I’m supposed to be getting smarter the more I do this right?!