Go Big or Not At All

I’m often asked, do you miss your power tools, and if so which one?

The honest answer is not really. I do truly enjoy working with hand tools and all the cliche reasons you have heard me spout for years now. I also recognize that power tools have their place and I can get as excited as the next guy and grunt like Tim Allen when I see a nice power tool. But my working rhythm just doesn’t need them anymore. It would actually slow me down to introduce a power tool these days in that I would have to rethink my entire process. Eventually once the reorganization were over my pace would pick up but the transition from hand process to machine process is, well, a process. It takes time and space to make this change in action and thought.

The honest answer is not really. I do truly enjoy working with hand tools and all the cliche reasons you have heard me spout for years now. I also recognize that power tools have their place and I can get as excited as the next guy and grunt like Tim Allen when I see a nice power tool. But my working rhythm just doesn’t need them anymore. It would actually slow me down to introduce a power tool these days in that I would have to rethink my entire process. Eventually once the reorganization were over my pace would pick up but the transition from hand process to machine process is, well, a process. It takes time and space to make this change in action and thought.

It could be as simple as the time required to move and set up a tool for work, but often this requires displacing something else in a small shop. So careful thought and grouping of tasks must take place in order to maintain some level of efficiency. You don’t want to do all the set up and break down of a power tool only to realize you forgot something 10 minutes later and have to do it all over again. I’m prone to this already, so trust me, I don’t need that headache.

These days I work in the order that the project dictates as I build piece by piece. It makes it real easy to pick up anywhere in a project without losing stride no matter how long you have in the shop on a given day.

These days I work in the order that the project dictates as I build piece by piece. It makes it real easy to pick up anywhere in a project without losing stride no matter how long you have in the shop on a given day.

However, there is one exception to this for every project: milling the lumber. Even if you mill each piece individually then move on to joining it there is still somewhat of a set up and take down process. I use specific tools and vises and bench space when I’m milling lumber. Whether it is all the wood for a project or just the parts for a drawer. My thought process and focus is different when milling too. Joinery is a micro focus task whereas milling is much more macro scale and about heavy lifting and not finesse. It sounds subtle but it is a different mindset that again takes time to make the transition to and from.

What’s the point Cap’n Verbose?!

My point is this is where I do miss a power tool. But not just any power tool, a highly dedicated and beefy power tool. Not one that will limit my capacity or require me to move it around and set it up. One that has a dedicated space in the shop where I just have to flip a switch and get my work done without a lot of fuss and changing of my thought process.

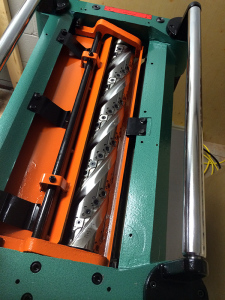

I’m talking about a thickness planer. A floor model, 20″ spiral headed monster! With my shop remodel coming together I have dedicated a spot in the corner where the planer and dust collector can sit and just do their job. I still have to do my jointing and finish planing by hand and wouldn’t have it any other way. But when it comes to quickly sizing parts (like when I have 30 minutes until I have a live demonstration) this planer will be gold. Moreover I have access to some wide boards so if I’m going to get a power tool, I might as well go big and get one that can handle the stock I can throw at it.

I’m talking about a thickness planer. A floor model, 20″ spiral headed monster! With my shop remodel coming together I have dedicated a spot in the corner where the planer and dust collector can sit and just do their job. I still have to do my jointing and finish planing by hand and wouldn’t have it any other way. But when it comes to quickly sizing parts (like when I have 30 minutes until I have a live demonstration) this planer will be gold. Moreover I have access to some wide boards so if I’m going to get a power tool, I might as well go big and get one that can handle the stock I can throw at it.

I will still need to pull out the bench planes to plane at least a reference face but now I can just pull the Fore plane off the shelf and flatten the face in a minute and let the planer take me home.

My process is just more streamlined now and while I could achieve this with a benchtop planer set up on a stand in the same dedicated corner, why not put the same care into getting the best tool for the job as I do with my joinery planes and hand saws. Stay tuned for a thorough review of this planer as well as what my milling schedule looks like now. In fact I think you will find that not every board I use will go through this planer and there will still be a significant amount of hand milling going on.

So here I sit waiting for the slings and arrows of the hand tool camp to fly my way.

That’s okay I have a really big planer to hide behind to block all those missiles.