Nice Roubo Bench…Do You Work Out??

In the Bally’s Total Woodworking Club meat market I can strut proudly when I show off my Roubo workbench and testify to it’s pumpitude by showing off the empty bottle of Ibuprofen for my sore muscles! In an earlier post where I talked about wood movement, I had started laminating the bench top into 6 inch wide sub-assemblies.

I got two of these done before I read a post by Mark (Loogie) on Lumberjocks about the building of Bob’s Bench.

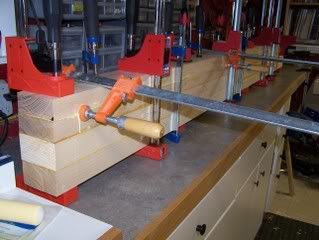

Mark mentioned a technique he was using to keep the individual boards in line with one another to decrease the amount of flattening that would need to be done later. By glueing up the top one piece at a time, he could run a clamp perpendicular to the clamping pressure across the joint thereby clamping the boards into alignment. Any more than 1 board at a time and the thickness would be too great for your average clamp.

While in hindsight this seems pretty obvious, it was a revelation at the time so thank you Mark. I immediately stopped making my sub-assemblies and starting adding one piece at a time. This kept my boards in almost perfect alignment as I started to build the top.

Here’s 3 boards in the clamps

Roll on some more glue and now 4 boards in the clamps

At this point my bench is in 3 pieces. Two 6 inch wide, 3 board assemblies, and one 7 inch wide, 4 board assembly. I had already jointed the 6 inch assemblies and using the new clamping technique had allowed me to form the 4 board assembly almost flat already so I skipped the jointer (mine is only 6″ anyway) and went straight to the planer to flatten completely. This is where the workout really got hairy. I wanted to make sure all 3 of these assemblies were exactly the same width so I could continue to use Mark’s clamping strategy to control the final glue ups since from here on out, only handplanes can tame this massive beast due not only to limitations in machine width capacity, but sheer weight.

With each one of these assemblies weighing in over 50 lbs, I took very light cuts with the planer and made sure I have perfect infeed and outfeed support. This adds a new element of safety to woodworking because dropping one of these would definately break a foot. After breaking a serious sweat making 3-4 passes through the planer with these beauties (don’t worry I got it on film so y’all can laugh at me later) I was at a uniform thickness and flatness all around.

Time to get serious about glue up. I could continue to use Mark’s technique by clamping across the joint on the very ends, but in the middle I would need to make some cauls.

These are just some scrap wood (I’ve got plenty of Ash laying about) covered in packing tape to prevent glue from sticking. I even planed a slight crown to the boards to provide extra pressure in the center of the caul across the joint. Now I could roll on even more glue, and, oooommmfff! Lift a 50 lb assembly on top of another one to make a 7 board glue up.

More glue, heavy lifting, and a hernia later and I had 10 boards glued and clamped.

This is the main bench assembly after I scraped off the glue using my number 80 cabinet scraper. The bench top now measures 4 inches thick, just over 8 feet long, and 19 inches wide.

It’s enough to bring a woodworker to tears. Just gazing out over the sea of laminated Ash! OK no more waxing poetic! Next I’ll flush up the ends using the same technique I used to cut the bottoms of the legs by cutting with a circular saw from both side and evening the face out with a flush trim bit in the router. I will keep the bench at this width to lay out the cavity for the end vise, then I can add the dog block and final laminations to bring the bench to around 26 inches.

I need to go rest my muscles now!