Sharpening Curved Blades

When it comes to moulding plane irons and carving chisels my philosophy is to not sharpen. I prefer only to hone. In both instances my cutting edges don’t encounter a lot of abuse so I’m not having to grind out a nick in the edge or re-shape a bevel angle. My moulding planes only get used after the bulk of the wood has been removed by the rabbet plane and a tough day for my carving chisels is being tapped lightly by a lightweight mallet through a forgiving wood like Mahogany, Walnut, or Basswood. So these tools usually only see the strop. I have a Butz bench strop that handles just about everything and recently got one of those Flexcut Slip Strop

When it comes to moulding plane irons and carving chisels my philosophy is to not sharpen. I prefer only to hone. In both instances my cutting edges don’t encounter a lot of abuse so I’m not having to grind out a nick in the edge or re-shape a bevel angle. My moulding planes only get used after the bulk of the wood has been removed by the rabbet plane and a tough day for my carving chisels is being tapped lightly by a lightweight mallet through a forgiving wood like Mahogany, Walnut, or Basswood. So these tools usually only see the strop. I have a Butz bench strop that handles just about everything and recently got one of those Flexcut Slip Strop for my carving chisels. Really this block is mostly for my V tools since I strop the gouges on the Butz strop. Constant vigilance is the watchword here (and a Mad Eye Moody catch phrase). You never want your tools to get so dull that a strop won’t do the job. However after a while stropping can round over a cutting edge. This effect is usually called “dubbing” and it is caused by the somewhat flexible nature of the leather. AS you press and iron into the leather it moulds around the edge and over time the iron takes on the rounded shape. So at some point, you need a coarser solution to reshape the cutting edge.

For me this coarser method usually means my water stones. I use my grinder only to remove a lot of metal, though lately I have been pulling out the Tormek for some of my really difficult shaped carving gouges like backbents and veiners. The problem with even ceramic water stones like my Shaptons is that the usually narrow blade will quickly take your stone out of flat. This is why you see so many carvers who are big fans of oil stones which will resist dishing a lot more than a much more friable water stone. For me though I have used oil stones a significant amount at the Steppingstone Museum, I don’t want them in my own shop. I have committed to water as a lubricant and adding in a system that will require oil would just make for a bigger mess. I try to keep sharpening as simple as possible and confined to a small dedicated space. So a few years ago I jumped on a new product made by DMT. The Diamond Wave

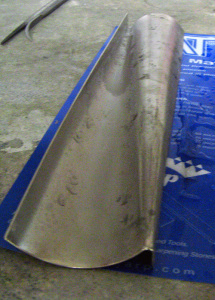

For me this coarser method usually means my water stones. I use my grinder only to remove a lot of metal, though lately I have been pulling out the Tormek for some of my really difficult shaped carving gouges like backbents and veiners. The problem with even ceramic water stones like my Shaptons is that the usually narrow blade will quickly take your stone out of flat. This is why you see so many carvers who are big fans of oil stones which will resist dishing a lot more than a much more friable water stone. For me though I have used oil stones a significant amount at the Steppingstone Museum, I don’t want them in my own shop. I have committed to water as a lubricant and adding in a system that will require oil would just make for a bigger mess. I try to keep sharpening as simple as possible and confined to a small dedicated space. So a few years ago I jumped on a new product made by DMT. The Diamond Wave is a cool product that combines and constantly changing concave and convex surface with the durability of diamond. It is a 2 sided stone with fine and extra fine grits on each side. With it I am able to match any gouge sweep or moulding iron profile, and remove more steel to clean up a dubbed edge. I can then flip the steel over and remove the burr or add a back bevel in some cases with my carving gouges. It is lubricated with water and has proven to be the perfect solution for my shop. Once I have cleaned up my edge I can then go back to the strop to bring the edge to its final sharpness.

It really is an ingenious tool that I have come to rely on. Though I admit it gets taken for granted because as I said at the outset of this article, I usually just need to strop my tools. I’m only writing about it now as the time came for a whole bunch of my carving gouges to retouch the edges and the Diamond Wave made my life so much easier. There are a lot of solutions out there for carving gouges and moulding irons but for something simple and inexpensive, the Diamond Wave can’t be beat. Give it a shot.

Your Turn

How do you sharpen your curved edges? Please share your thoughts and experience in the comments section below.

**The above links are affiliate links. Thank you for supporting my blog by using these links to purchase tools.