Why You Need a Resaw Frame Saw

I think I have had my Roubo style frame saw now for about 6 months. (See it in action here)I have been playing with is and resawing everything from scraps to actual project parts. I have sawn out veneer as thin as 1/8″ and bisected 8/4 and 12/4 boards on scraps and even actual project parts. There was something of a learning curve to get used to the weight of the saw and how to guide it with the 2″ wide blade and that curve was flattened a bit when I added a 4″ wide blade from Blackburn Tools. I am extremely happy with this resawing frame saw and still am surprised at the attitude of my esteemed colleague Adam Cherubini over this saw. Mine works great. Maybe it took some practice and tweaking of the set to get it humming along but it works great.

I think I have had my Roubo style frame saw now for about 6 months. (See it in action here)I have been playing with is and resawing everything from scraps to actual project parts. I have sawn out veneer as thin as 1/8″ and bisected 8/4 and 12/4 boards on scraps and even actual project parts. There was something of a learning curve to get used to the weight of the saw and how to guide it with the 2″ wide blade and that curve was flattened a bit when I added a 4″ wide blade from Blackburn Tools. I am extremely happy with this resawing frame saw and still am surprised at the attitude of my esteemed colleague Adam Cherubini over this saw. Mine works great. Maybe it took some practice and tweaking of the set to get it humming along but it works great.

However during all of this learning and testing I was working with 6-8″ lumber that my bandsaw could have handled (albeit slowly). So this weekend when I clamped up a 12/4x24x50 piece of Walnut in my leg vises, I did so with a bit of trepidation. Would my endorsement of this saw go out the window when it really counts? After all, isn’t this kind of size of cut why I built the saw in the first place? Other than a $6,000 bandsaw or a Woodmizer, resawing a plank more than about 15″ wide just isn’t possible in the home wood shop. Forget about the speed of the cut or how many calories you burn doing it; just being able to make the cut is all we are talking about with wide boards.

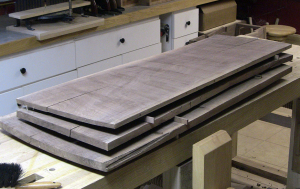

Well long story short, my frame saw passed the test with flying colors! In fact I estimate I was cutting about 1″ per minute with this saw. I set up a stop watch and started sawing. Every 4 minutes I switch sides in order to better control the alignment of my kerf (and rest my muscles). On Friday in the time of 46:27 of actual cutting time, I was able to cut away a 1x24x52″ slab. On Saturday, I repeated the process and sawed away an identical slab in 52:48. I think the blade was getting dull in the final foot of sawing on this second cut. I’m left with a 3/4″ thick slab of Walnut to add to my lumber rack since I only needed two pieces for the drop leaf table I’m making.

The biggest lesson learned from these big cuts is how much a tiny deviation in alignment can add up over the course of a big board like this. Standard practice is to saw in from each end to the halfway point and have your saw cuts meet in the middle. After sawing in from one end during my first attempt, I started on the other side. I realized about 15″ into the cut that I was drifting a bit on one side and began to “steer” as best I could to straighten out the cut. Unfortunately with only about 8″ left to saw through I was not able to correct completely so I kerfs did not meet and I had to lever the two pieces apart with my Froe. This left an ugly looking flap in the middle. Fortunately this was quickly cleaned up with a Fore plane and I had a flat-ish face to reference my marks for the second saw cut.

My second time around, I made my first cut as planned, then started on the other end. This time after I had sawn in about 1/3 of the way, I stopped and connected my kerfs down the edges using a typical 26″ hand saw. I sank this “guide” kerf about 1/8″ deep then clamped the whole slab vertically for sawing again. While these kerfs won’t allow you to saw on auto pilot they do stack the cards in your favor by giving the saw a suggested exit point. My resulting second resaw met exactly and the boards came apart with no effort. In fact the tiny ridge shown is not a factor of misalignment but rather the start of a new kerf when the boards suddenly clamped together under the pressure of my leg vise and my saw kept moving forward for half a stroke.

In the end, just being able to saw these boards out is an accomplishment to be proud of that saves you from wasting wood and turning it into saw dust. But being able to make a clean cut that will significantly reduce the amount of time taken to plane the surfaces is something to make you burst into song.

What I think is most exciting is that this saw isn’t just something for the diehard hand tool woodworkers to get excited about. Even the deafest power tool user can’t help but see the benefit of a tool that will allow them to work with really wide and/or thick lumber that only the most expensive, industrial sized machines can handle. Yes you will need to practice with it and a modicum of hand sawing expertise is helpful, but think about what this means for your finished projects. Not only that, but the speed in which this saw cuts is really astounding. I realize that my 14″ bandsaw is pretty underpowered, but I know I can resaw a typical 6-8″ wide board faster than it can. I have timed it and my hand method beat the bandsaw by 2 minutes on a 7×24 piece of old growth heart Pine for drawer sides. I’m not a super sawyer, I chose the right tool for the job.

So, after extensive field testing, I honestly can say that a frame saw like this is worth the time and effort to build. It is a lot of fun to use, and not that tiring since the power comes from your legs primarily. Plus your neighbors look at you with new found respect when they see you dancing with this beat of a saw.